This content was originally published on OldHouseOnline.com and has been republished here as part of a merger between our two businesses. All copy is presented here as it originally appeared there.

First manufactured in the late 19th century as safety glass, wire glass doesn’t shatter easily, is fire-resistant, and maintains its integrity when broken. The design is simple, just wire mesh (often farmyard chicken wire) embedded during manufacture in a sheet of plate glass. Insurance companies, city and state governments, and builders were quick to recognize its value. By the turn of the 20th century, wire glass was required in buildings from schools to firehouses and city halls, and used in skylights, windows, and transoms.

Wire glass is no longer required by safety and fire codes, but it got instant status as a salvage item. Homeowners Gretchen and Ray Master had foresight when they chose it for their late 19th-century loft in Brooklyn. They installed it not only in transoms and doors but also in room dividers. To improve energy efficiency and provide soundproofing, and to guard against accidental breakage, the couple added clear ¼“ tempered glass behind each ¼“ wire glass panel, leaving an insulating ¼“ airspace in between.

Cutting Old Glass

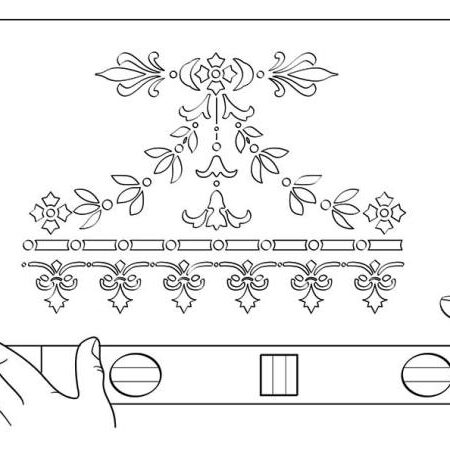

1. Prep Glass

There’s an art to cutting old glass, including wire glass. It can be learned. As with any project, start with the right tool. In the case of wire glass, you must have a very good glass cutter tool, such as a Red Devil. Polish the glass first with a water-based abrasive cleanser like Gumption to induce microfractures, which encourages the glass to crack along the track of the cutting wheel.

2. Mark + Cut

Take a Sharpie to mark where you want to cut, using a straightedge to make sure the line is even and straight. Lubricate the glass before you begin (WD-40 works well) to make sure the cutter wheel spins smoothly. Then score the glass by firmly rolling the glass cutter across the glass in one cut-don’t stop and start, and be sure to use steady but not excessive pressure. Lift the glass and tap along the opposite side of the score line with the knob of the cutter until a crack appears. Then continue every few inches to make a series of cracks. When you have a complete line, take the glass with two hands (wearing protective gloves) and break the cut piece off with a sharp snap of your wrists. You can snip off any extra wire along the edges using wire cutters.